-

联系我们

-

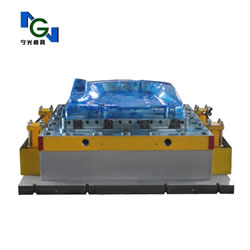

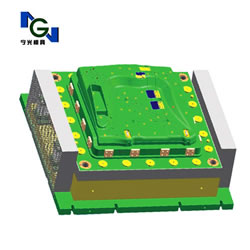

SMC Tooling

Ningguang Mould is specilized in manufacturing tooling for SMC and BMC materials.

SMC Mould tooling and BMC Mould tooling are usually designed with hydraulic cylinders with flow diverters for the ejection side. Many of the SMC tooling and BMC toolings are polished to diamond finish and textured prior to chrome plating.

SMC tooling and BMC tooling normally heated by oil and steam. The temperature directly affects the products' quality and production efficiency. The tooling with a uniform temperature will fill easier and produce parts with less warpage, improved dimensionnal stability and uniform surface appearance. Achieveing a uniform tooling temperature is dependent on the method of SMC toolings and BMC toolings heating.

A tooling that is heated by steam or oil will have a uniform temperature because the heat source maintains a constant temperature. Electrically heated SMC toolings and BMC toolings are more difficult to maintain at a uniform temperature because the cartridge heaters are contantly cycling on and off. When they are on, they generate a great deal of heat at the source but this heat must be dispersed throughout the tooling in a way that produces a uniform toolings temperature.

Heating the SMC tooling and BMC tooling by steam is faster than by oil. Temperature is uniform, but not easy to control; while oil heating, the temperature is more uniform than steam, and stability, but pollute the environments. However, oil as a heat sourse, is only about half as efficient as steam. Therefor, when using oil to heat a tooling, it is necessary to set the oil temperature higher than the desired tooling temperature.

Whatever your SMC tooling or BMC tooling needs we have the design & manufacture capabilities to fulfill them.

-

SMC模具新闻

- 2014-5-19SMC Mould Advantage...

- 2014-5-17Treatment of SMC Mould products later...

公司地里位置